What happens when the promise of faster, cheaper, and greener construction collides with the hard reality of risk? Across the globe, developers are embracing innovative building techniques—mass timber, modular manufacturing, and even robotics—hoping to revolutionize an industry plagued by delays and escalating costs. Yet, a hidden barrier looms large: insurance. Skyrocketing premiums and shrinking options are forcing builders to rethink whether these cutting-edge methods are worth the financial gamble. This clash between innovation and caution is reshaping how the world builds.

The stakes couldn’t be higher in an era of housing crises and sustainability demands. As urban centers grapple with affordability and environmental goals, non-traditional construction offers a potential lifeline. However, insurers, wary of unproven materials and methods, are slamming on the brakes, creating a ripple effect that impacts developers, policymakers, and communities alike. This tension reveals a broader truth about progress: even the most promising advancements can stall when trust and data lag behind ambition.

The Surge of Innovative Building Techniques

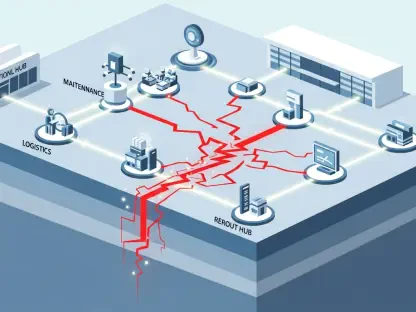

The construction sector is undergoing a seismic shift as traditional methods struggle under supply-chain bottlenecks and labor shortages. Techniques like mass timber, using cross-laminated timber for high-rise structures, and modular building, where components are prefabricated off-site, are gaining ground for their efficiency. In dense markets like San Francisco, modular units can be assembled swiftly, bypassing the need for large on-site crews and slashing timelines significantly.

These innovations aren’t just about speed—they’re about survival. With labor costs soaring and materials like steel facing tariffs, developers are turning to alternatives that promise savings and sustainability. Mass timber, for instance, offers a lighter carbon footprint compared to concrete, aligning with green building mandates. Yet, beneath the surface of these advancements lies a growing unease among insurers, who see uncharted risks in every new beam or module.

Insurance Challenges Stifling Progress

For insurers, the adoption of non-traditional methods presents a complex puzzle. A key issue is the lack of historical data—without decades of performance metrics on materials like mass timber, underwriting becomes a speculative exercise. Research from Aon underscores this gap, noting that insurers struggle to assess long-term durability, leading to heightened caution in policy offerings.

Beyond data shortages, perceived risks drive up costs. A Gen Re study indicates that timber-based projects can face premiums up to 2.4 times higher than masonry builds due to concerns over fire and water damage. Compounding the problem, fewer insurers are willing to take on these projects. Kris Bauer, SVP of Construction at Jencap Group, estimates a 20-40% reduction in available carriers for non-traditional builds, particularly in high-risk zones like coastal Florida. This limited market translates to tighter capacity and steeper prices.

The financial implications are stark for developers. While a modular project might save millions in upfront costs, the added expense of insurance can erode those gains. Residential developments, in particular, face coverage constraints, forcing tough decisions on whether to push forward with innovation or revert to conventional, insurable methods. This dynamic illustrates a critical bottleneck in the industry’s evolution.

Industry Perspectives on the Risk-Innovation Divide

Insights from the field paint a vivid picture of the struggle. Kris Bauer describes a stark contrast in the insurance landscape: “The marketplace for non-traditional projects is far more limited than for a standard concrete-steel structure or even traditional wood-frame.” He highlights that while modular construction can relocate production to cost-effective regions, the resulting insurance premiums often offset those savings, creating a frustrating trade-off.

Looking ahead, Bauer points to emerging frontiers like robotics and 3D-printed homes, which introduce fresh uncertainties. Risks such as cyber vulnerabilities in automated systems and untested structural integrity pose new challenges for underwriters. Despite this, optimism persists. Bauer believes that as successful projects accumulate and data builds, more insurers will enter the fray, much like they adapted to early space exploration risks. This perspective underscores insurance as a lagging but eventual supporter of progress.

The real-world impact is evident in daily negotiations between developers and carriers. For every innovative project pitched, the question of risk looms large, often dictating whether a vision becomes reality or remains a blueprint. This ongoing dialogue between builders and insurers shapes not just individual projects but the broader trajectory of construction innovation.

Strategies to Bridge the Insurance Gap

Navigating this challenging terrain requires strategic foresight for developers and brokers. Bauer emphasizes the importance of early collaboration with specialized brokers to create robust underwriting submissions. Detailed documentation of contractor expertise, material testing protocols, and logistical plans can help build insurer confidence, even when dealing with novel methods.

Another critical step is crafting a compelling risk narrative. For mass timber or modular builds, underwriters seek assurance on safety and consistency—questions like whether modules are uniformly manufactured or if installers are certified must be addressed upfront. Demonstrating rigorous quality control in factories can tip the scales in favor of coverage, even if at a premium.

Finally, a thorough cost-benefit analysis is essential. Developers must calculate if savings from innovative methods outweigh the elevated insurance costs and stricter terms. Staying informed on evolving data trends also helps—over time, as insurers grow comfortable with these approaches, terms may ease. Until then, stakeholders must brace for an “innovation premium” as the price of pushing boundaries.

Emerging Horizons in Construction Technology

Peering into the next wave of advancements, the industry stands on the cusp of transformative change with AI-driven tools, robotics, and 3D-printed homes. While still in early stages, robotics is already appearing in modular factory settings, though high costs limit widespread adoption. Bauer notes that as technology becomes more affordable, traditional contractors will likely embrace it, forcing insurers to adapt as they did with satellite risks decades ago.

These futuristic methods bring a new spectrum of concerns, from cyber threats in automated systems to questions of long-term durability. Regulatory hurdles and performance uncertainties further complicate the risk profile. Yet, the excess and surplus (E&S) market, known for tackling novel risks, is poised to lead the charge, setting the stage for broader acceptance.

As data accumulates from pilot projects, the insurance sector’s hesitance may wane. Bauer predicts that once underwriters witness consistent success, more carriers will join the market, reducing costs and expanding capacity. This gradual shift hints at a future where even the most radical construction ideas could find a secure footing, provided patience and proof align.

Reflecting on a Path Forward

Looking back, the journey of integrating new construction methods into mainstream practice revealed a profound tension between innovation and risk. Developers who dared to experiment with mass timber or modular builds often found themselves caught between the allure of efficiency and the burden of insurance barriers. Each project became a test of resilience, balancing ambition against financial realities.

The lessons learned pointed toward collaboration as a cornerstone for progress. By forging stronger partnerships with brokers and insurers, builders paved the way for better risk narratives and data sharing. Those who anticipated the “innovation premium” and planned accordingly often navigated the hurdles with greater ease, setting a precedent for others to follow.

Ultimately, the path ahead demanded persistence and adaptability. Embracing early engagement, staying ahead of data trends, and weighing costs with precision emerged as vital steps for stakeholders. As the industry moved forward, these strategies promised to turn today’s challenges into tomorrow’s triumphs, ensuring that the future of construction could be both bold and secure.